B&B Line

Metalworking in all its forms for the products of tomorrow.

B&B Line designs and manufactures bespoke metal solutions for the interior design, bathroom furniture, contract, and related sectors.

Cutting and sectioning, sheet metal and tube laser cutting - Bending, calendering, tapering - CNC machining - Welding - Cleaning and smoothing - Surface finishes - Assembly and packaging -

How we can help

We shape metal by shaping ideas.

At B&B Line, we aim for quality in all its forms: product precision, production efficiency, and customer value. If it sounds bold, that’s because it is.

We do this by listening to the needs of our customers, collaborators, suppliers, and partners, to find the most innovative solutions with passion and creativity.

We create

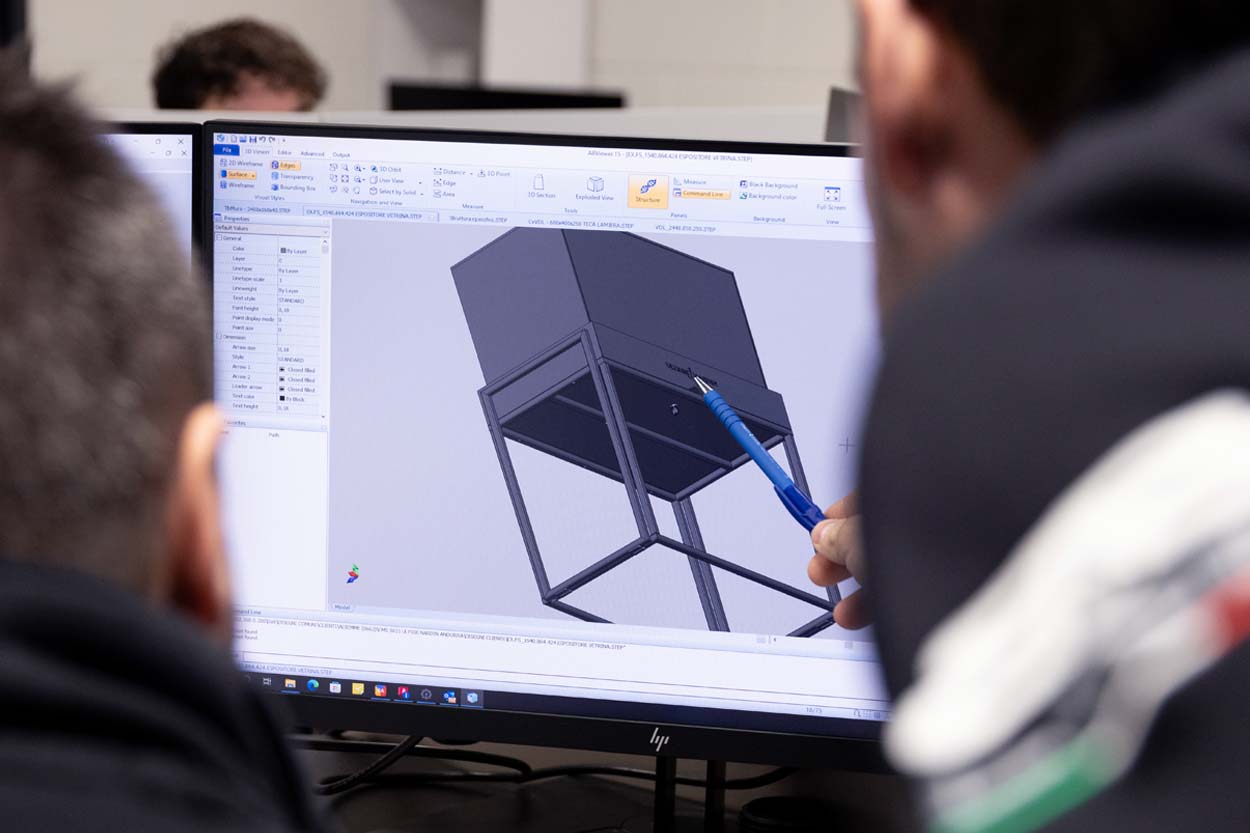

Co-design

Based on our customers’ ideas and needs, we create 2D and 3D rendered layouts to share internally and with our supply chain. This allows us to find the right aesthetic and functional solution that meets the customer’s requirements.

We test

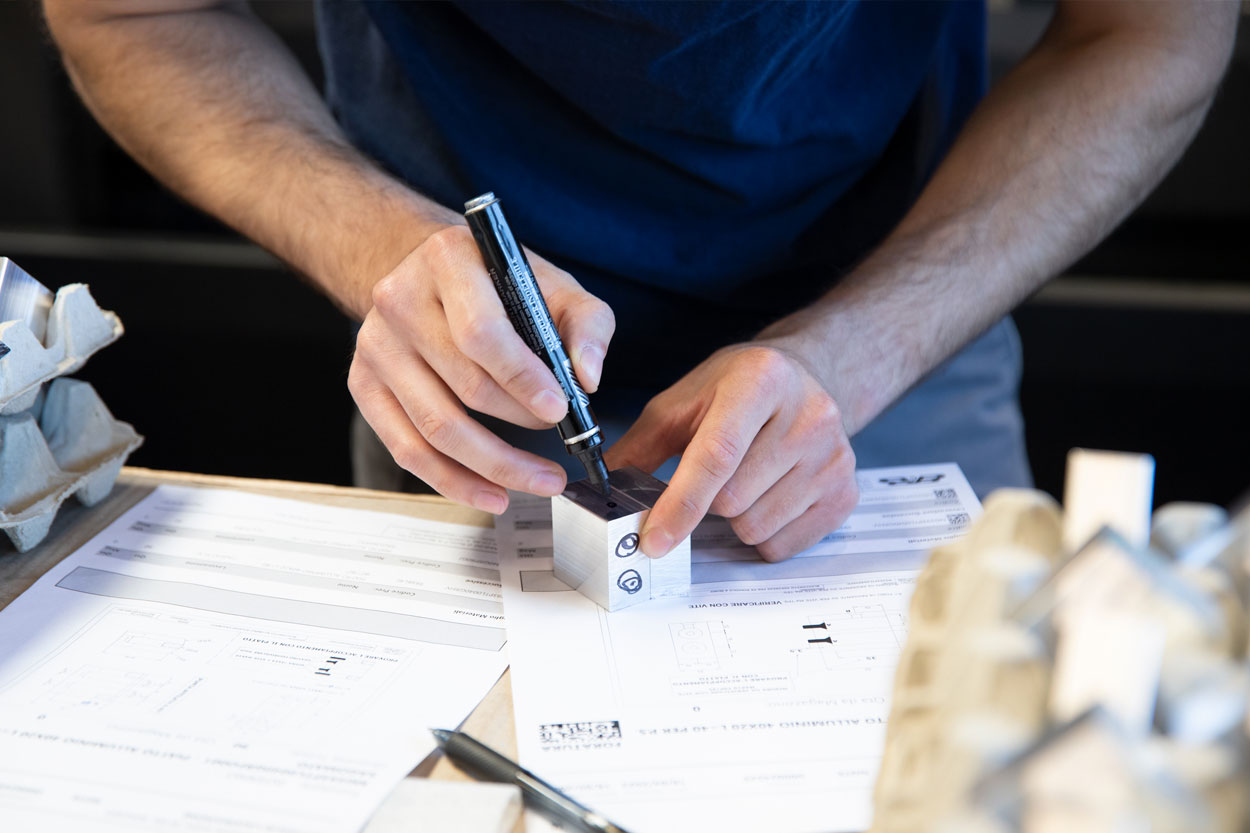

Prototyping

We analyse every construction challenge to consistently create the right forms, respecting both design and function. Once the prototypes are approved, we can industrialise and manufacture each component down to the smallest detail.

We produce

Production

We bring projects to life through industrialisation at every stage — from sourcing to final delivery. We handle fast turnarounds and small or large batch orders, supported by Kanban management for high-turnover products.

Shared design

Prototype creation

Product manufacturing

Logistics and shipping

Our specialisations

We work with high-tech technologies.

Using the best technologies requires a mindset geared towards progress. At B&B Line, we can handle large-scale orders alongside smaller projects.

All of this is possible thanks to our internal processes and a fast, reliable supply chain, leveraging cutting-edge technologies and the know-how gained through experience.